Pourquoi l'assurance qualité des poignées de bagages n'est-elle pas négociable?

Dans le monde B2B de la fabrication de bagages, a faulty luggage handle is more than just an inconvenience—it’s a critical point of failure that damages a brand’s reputation and increases warranty claims. As a dedicated supplier of wholesale luggage components, our mission is to deliver exceptional stability and consistency.

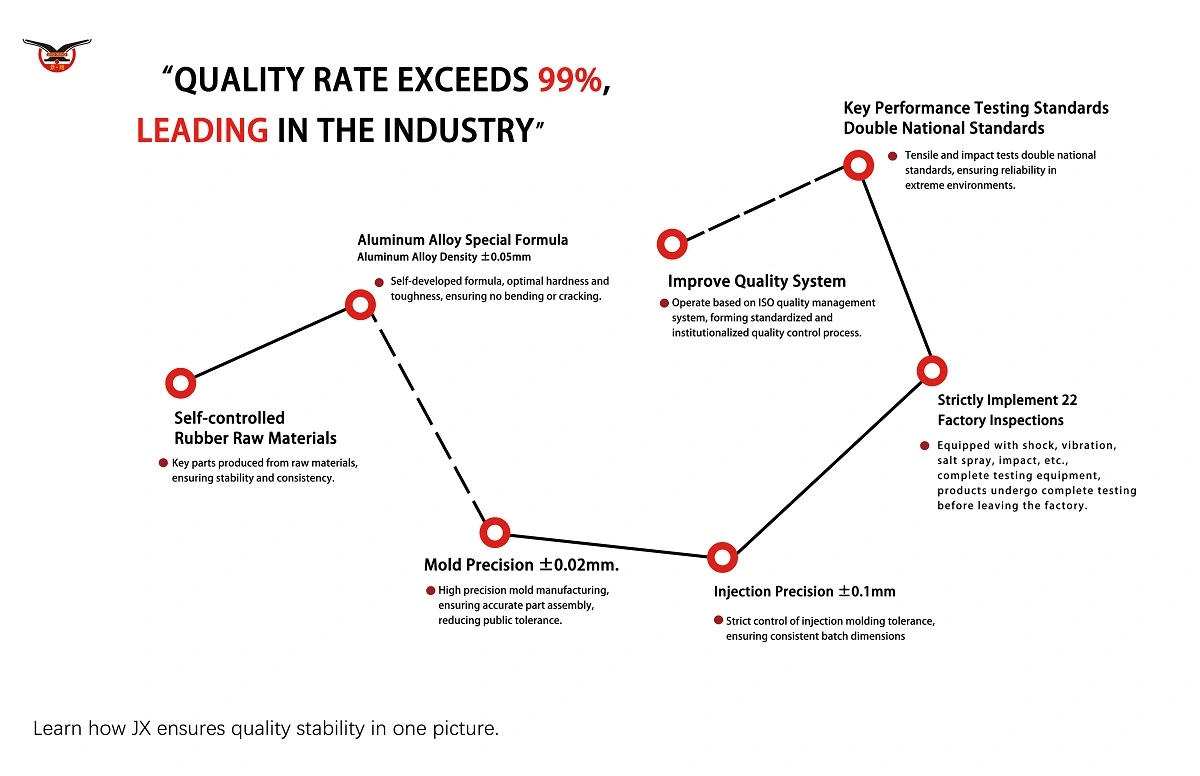

At JX, our commitment is quantified: “Quality Rate Exceeds 99%, Leading in the Industry.” This achievement is built upon a transparent, systematic process designed specifically to address the demanding needs of global luggage brands.

This article details the seven critical steps we take—from raw material control to final inspection—to ensure unwavering luggage handle quality assurance and reliable supply for your bulk orders.

Phase I: Material Control—Building Stability from the Ground Up

The stability of the telescopic handle comes from its core material. We not only purchase standard plastic parts and aluminum materials but also carefully design them.

1. Self-Controlled Rubber Raw Materials

The key rubber parts dictate the telescopic handle’s feel and function. We produce these parts in-house from raw materials. This ensures batch-to-batch stability and eliminates external material risks.

2. Exclusive formula for aluminum extrusion (aluminum precision ±0.05mm)

Our luggage handles utilize a self-developed, proprietary aluminum alloy. This formula achieves optimal hardness and toughness, controlled to a strict density tolerance of ± 0.05 MM. This specialized material science ensures the telescopic handle maintains its integrity during long-term use, preventing common issues like bending or cracking.

Phase II: Manufacturing Precision—Guaranteeing Fit and Function

Tight tolerances are essential for a smooth, rattle-free luggage handle. Our process eliminates the guesswork associated with third-party components.

3. Mold Precision (± 0.02 MM)

Precision is non-negotiable for a smooth and durable luggage handle. We employ high-precision mold manufacturing, holding the component tolerance to a remarkable ± 0.02 MM. This extremely tight accuracy ensures precise part assembly and dramatically reduces fitting errors, crucial for high-volume manufacturing.

4. Injection Precision (± 0.1mm)

Strict control over injection molding is essential for batch consistency. By controlling the tolerance to ± 0.1 MM, we ensure that every single handle component maintains the required dimensional stability, guaranteeing uniform quality across your entire order.

Phase III: Systemic Quality Inspection—Double the Assurance

Consistency in quality requires consistency in management. Our quality system is the engine that drives our 99% success rate.

5. Strictly Implement 22 Factory Inspections

Our final quality gate is comprehensive. All products undergo a complete check based on 22 rigorous factory inspections. These tests are performed using specialized equipment to check for:

- Shake and Vibration

- Drop and Impact

- Salt Spray

This multifaceted testing ensures every telescopic handle is ready to withstand real-world travel conditions before shipment.

6. Key Performance Testing Standards Exceed National Standards by Double

We test our handles to a level of durability that exceeds national testing standards by two times. By subjecting the luggage handles to elevated tensile and impact forces, we proactively confirm their reliability in extreme operational environments, giving you peace of mind.

7. Improve Quality System

Supporting the entire process is our commitment to standardization. We operate based on the ISO quality management system. This institutionalized and standardized quality control process ensures that checks are consistently and systematically applied, making our luggage handle quality assurance repeatable and reliable for every order.

JX Luggage Handle Quality Assurance Upgrade your brand

The JX 7-Point Quality Blueprint is our promise to you: fast delivery and stable quality. By controlling materials, enforcing hyper-precision, and implementing double-standard testing, we eliminate supply chain risks for our B2B clients.

Ready for a supply of consistently high-quality telescopic handles?

Contactez-nous today to discuss your OEM project and take advantage of our 99%+ quality commitment.

.webp)