Dans cet article, we’ll walk you through the key stages of our OEM telescopic handle manufacturing process, illustrated with exclusive glimpses from our factory floor.

At JX, we believe that excellence in manufacturing isn’t just about machinery—it’s about process, precision, and partnership. B2B clients seeking reliable, high-performance telescopic luggage handles can gain valuable insight into quality, durabilité, and design integrity by understanding how manufacturers make these components.

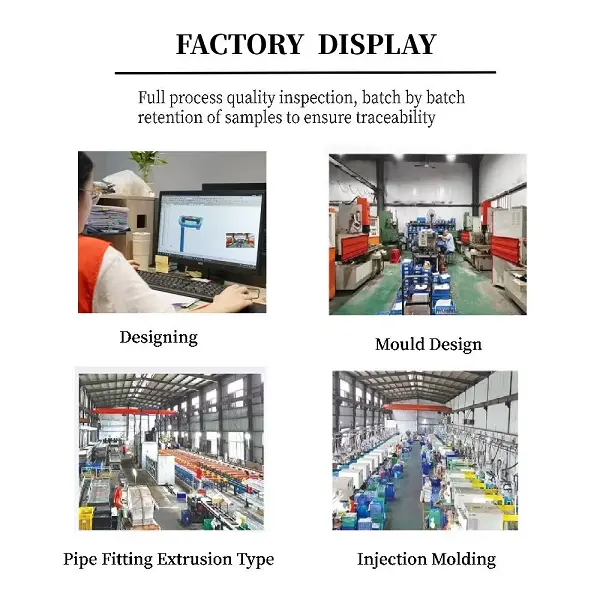

Stage 1: Conception & Engineering

It all starts with an idea—and a detailed digital blueprint.

The first stage of our process involves meticulous design and prototyping. Using advanced CAD software, our engineers develop precise 3D models of the telescopic handle, optimizing everything from ergonomics and extension mechanism to material thickness and structural integrity.

As seen in the first image, this phase is crucial for aligning with client specifications and ensuring that the final product meets both aesthetic and functional expectations.

Stage 2: Material Selection & Pipe Extrusion

Strength begins with the right materials.

We use high-grade aluminum alloys for our telescopic handles, with tube walls ranging from 1.2 à 1.5 mm for premium products—significantly thicker than the sub-1 mm walls found in economy-grade handles. This ensures superior load-bearing capacity and resistance to bending or deformation.

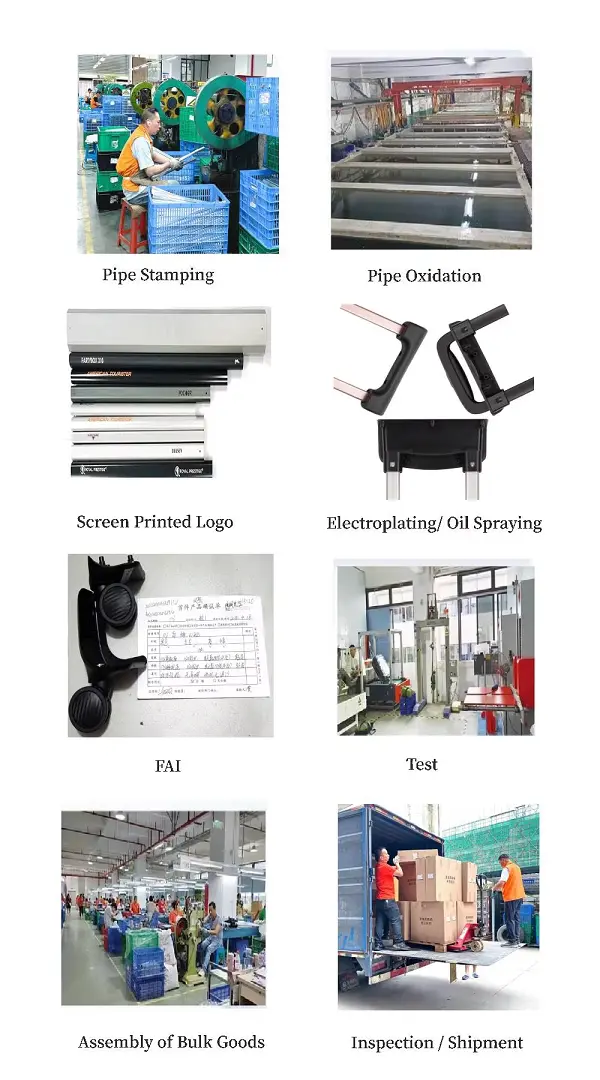

During extrusion, pipes are formed to exact tolerances. Additional steps, such as oxidation or oil spraying (as shown in the second image), enhance corrosion resistance and surface finish.

Stage 3: Estampillage & Hole Punching

Precision punching ensures smooth operation.

The punching process creates precise holes along the outer tube, enabling the inner tube to lock securely at multiple height settings.This step requires high-precision stamping machines to maintain consistency and avoid misalignment—a common cause of handle failure in lower-quality products.

Stage 4: Assemblée & Electroplating/Spraying

Where parts come together—and gain their finish.

Handles are assembled with internal springs, steel balls, and locking mechanisms. The second image highlights the electroplating or oil spraying process, which not only enhances appearance but also adds a protective layer against wear and environmental factors.

Logos can be screen-printed or laser-engraved at this stage for branded customization.

Stage 5: Quality Inspection & Testing

No handle leaves our factory without passing rigorous checks.

We conduct First Article Inspection (FAI), load-bearing tests, extension-retraction cycle tests, and salt spray resistance evaluations. By retaining samples from each batch, we ensure traceability and deliver consistent quality, a commitment highly valued by our OEM partners.

Stage 6: Shipping & Logistics

From our factory to your production line.

The final step is packaging and shipping. As shown in the third image, finished handles are carefully packed and palletized for secure transit. We work with global logistics partners like DHL and FedEx to ensure timely delivery to more than 120 pays.

OEM Telescopic Handle Manufacturing Process in JX Response Advantages

- Full-process control: From design to delivery

- Proven durability: test standards are twice as high as national standards

- Customization support: OEM/ODM available with quick sampling (3–5 days)

- Scalable order volumes: MOQ 500 sets, with bulk discounts

Explore Our Process—Build Better Luggage.

A well-made telescopic handle isn’t just a component—it’s the backbone of user experience in travel products. By controlling every step of the manufacturing process, we ensure that our handles offer silent retraction, smooth operation, and long-term reliability.

Interested in custom telescopic handles for your luggage line?

JX—Engineering Trust in Every Handle.

.webp)