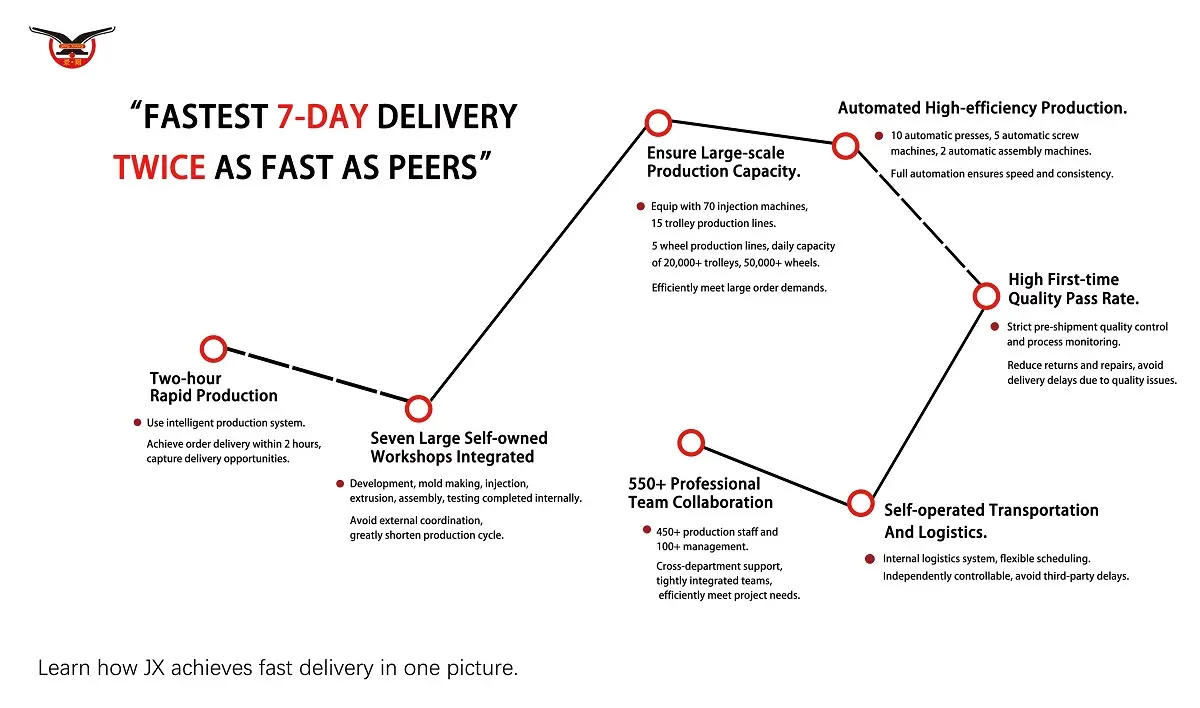

競争の激しい鞄製造業界において, 荷物ハンドルの配達速度は重要な差別化要因です. 多くのサプライヤーは 14 ~ 21 日のリードタイムに苦労しています, JX has engineered a seamless, self-controlled production chain that guarantees 7-day delivery of luggage handles—twice as fast as its industry peers. This blog breaks down the seven-step strategy behind our agile supply chain.

Step 1: 2-Hour Response: The Starting Point for Ultra-Fast Luggage Handle Delivery

JX’s intelligent production system initiates order processing within two hours of confirmation. By automating material allocation and workflow scheduling, we eliminate traditional delays and capture early delivery windows—a key advantage for brands targeting fast-moving markets.

Step 2: Seven Self-Owned Workshops for End-to-End Control

With integrated facilities handling development, mold making, injection, extrusion, assembly, and testing, JX avoids third-party dependencies. This vertical integration slashes coordination delays and reduces production cycles by 60%.

Step 3: Large-scale production capacity guarantee

搭載 70 injection machines, 15 trolley production lines, そして 5 wheel production lines.

Capacity Guarantee: Our daily capacity of over 20,000 trolleys and 50,000 wheels ensures we can efficiently meet your large-scale orders for telescopic handle sets and associated components.

This automation guarantees both speed and uniformity across large-scale orders.

Step 4: Automated High-Efficiency Production

Automation guarantees standardized processing for both speed and consistency—critical for the complex mechanisms of a luggage handle.

We employ 10 automatic presses, 5 automatic screw machines, そして 2 automatic assembly machines.

Step 5. High First-time Quality Pass Rate

Nothing delays luggage handle delivery more than quality issues requiring rework.

We implement strict pre-shipment quality control and process monitoring at every step.

Rigorous pre-shipment checks and real-time process monitoring minimize defects. By avoiding rework and returns, we eliminate quality-related delays—a common bottleneck in traditional supply chains.

Step 6: あ 550+ Professional Team

Our human resources are structured for maximum efficiency.

A robust team of over 450 production staff and 100 management personnel forms tightly integrated teams.

Cross-department support ensures swift internal coordination, efficiently meeting the specific requirements of your telescopic handle project.

Step 7: Self-Operated Logistics and Flexible Dispatch

JX’s internal logistics network enables dynamic scheduling and independent control over shipping. By bypassing third-party carriers, we avoid unforeseen delays and ensure on-time arrival.

Choose the Industry’s Fastest Luggage Handle Delivery.

JX integrates speed, quality, and integration into every aspect of luggage handle delivery. We offer more than just telescopic handles; we provide a highly efficient supply chain solution supported by seven workshops, automated production, and our own logistics system.

Choose us and gain a competitive edge in the global market—twice as fast as your competitors!

.webp)