Discover premium luggage trolley handle replacement suppliers offering the ultimate replacement handle luggage solution with this innovative telescopic handle! Engineered with dual-layer aluminum alloy tubing for an exceptional strength-to-weight ratio, it combines lightweight portability (ideal for 16-28-inch suitcases) with unyielding durability, effortlessly supporting heavy loads without bending.

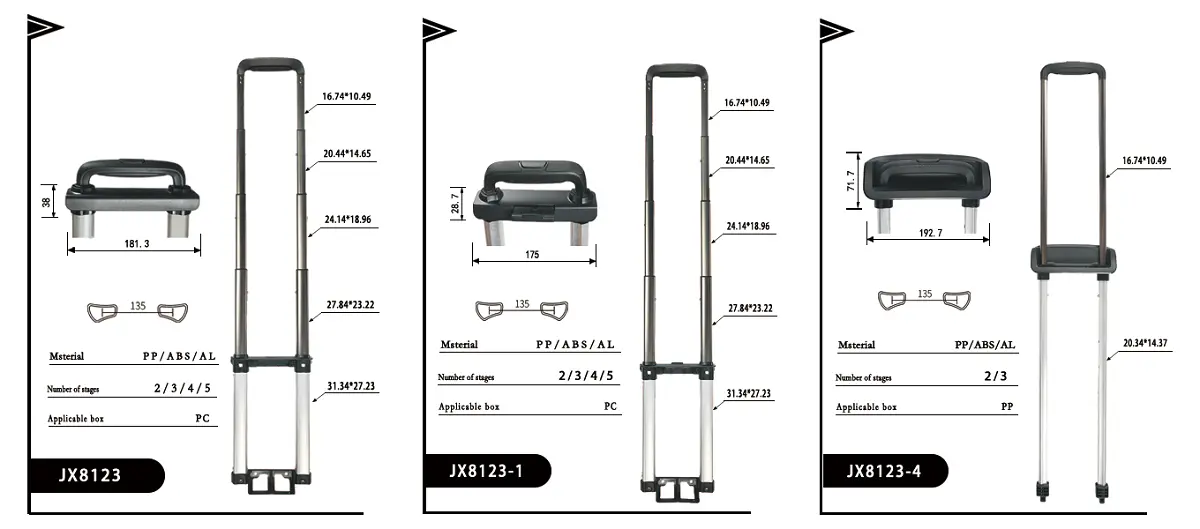

JX8123 Luggage Handle Replacement Features:

- Lightweight & Ultra-Sturdy: Slimmer yet reinforced inner/outer aluminum tubes reduce bulk by 15% compared to conventional handles while maintaining structural rigidity for smooth dragging across terrains.

- Ergonomic handle grip: The arched handle design with a satin-smooth finish conforms to natural hand curvature, reducing grip fatigue during extended use, while its modern bow shape adds sleek sophistication to any luggage.

- Customizable stage (2-5 stages): Adaptable telescopic design fits 16″-28″ cases, with a 5-stage extension maximizing height flexibility for diverse user heights and luggage frames.

- Universal Compatibility: Precision-engineered for seamless integration as a replacement handle for luggage across cloth/PC/ABS suitcases, backed by corrosion-resistant hardware for long-term reliability.

Perfect for luggage handle suppliers, Prioritizing versatility, this handle’s modular design (manual measurement tolerance ±1 cm) and high-hardness materials ensure travel-ready resilience. Upgrade your luggage systems today with a solution that balances form, function, and effortless installation!

Note: Customizable section counts require pre-order specifications. Always verify suitcase dimensions for optimal fit.

More Models of JX8123 Luggage Trolley Handle Replacement

Eco-Friendly Plastic Components

The telescopic handle’s plastic parts are crafted from non-toxic, environmentally friendly materials. Zero chemical odor ensures safety and a pleasant user experience.

High-Strength Aluminum Tubes

The telescopic handle integrates 6063 aluminum alloy tubes. With precision polishing technology, the surface boasts a rust-resistant, scratch-proof finish and 30% higher load-bearing capacity.

Industry-Standard Luggage Handles

As luggage parts handle suppliers, JX suitcase handles undergo rigorous testing to ensure compliance with global quality benchmarks. Every handle is engineered for reliable performance and longevity, backed by the following certified tests:

1. Shock Resistance Test

Purpose: Simulates repeated impacts during transit.

Parameters:

20-inch handle: 15 kg load, 500 cycles at 20 impacts/minute

24-inch handle: 20 KG load, 500 cycles at 20 impacts/minute

28+ inch handle: 25 kg load, 500 cycles at 20 impacts/minute

Standard Compliance: ASTM D256 (Impact Strength Test)

2. Fatigue & Durability Tests

Telescopic Pull Test:

5,000+ cycles of continuous extension/retraction (Refer to GB/T 3075 axial fatigue standard)

Button Endurance Test:

10,000+ presses on release buttons (Ensure that the buttons are flexible and not stuck for a long time)

3. Wobble Tolerance Test

Method: A custom tester measures front-back & left-right sway.

Acceptable Limits:

2-section: ≤10mm (±3mm)

3-section: ≤15mm (±3mm)

4-section: ≤20mm (±3mm)

5-section: ≤25mm (±3mm)

Design Advantage: Comply with the ISO 178 bending resistance standard

4. Ergonomic Pull Force

Max. Pull Force: ≤24 N (unit: Newton)

Optimized spring resistance design ensures easy and labor-saving one-handed operation

5. Luggage Trolley Handle Locking Mechanism Test

Procedure:

Apply 5-7 kg of force, swing forward-backward and left-right 5 times (lasting 20 seconds)

Requirement: The ball lock buckle does not loosen or retract (refer to ASTM E606 fatigue crack growth standard)

Application: Ensure that the tie rod is stably locked under bumpy road conditions

.webp)