JX Luggage Parts: Rapid Delivery & Premium Quality in Luggage Trolley System Manufacturing

Ranked #2 in sales volume within China’s mid-to-high-end luggage component industry, JX Luggage Parts has been a trusted partner since 1999. With over two decades of expertise, we have cultivated a unique competitive edge defined by two core pillars: rapid delivery and uncompromising quality.

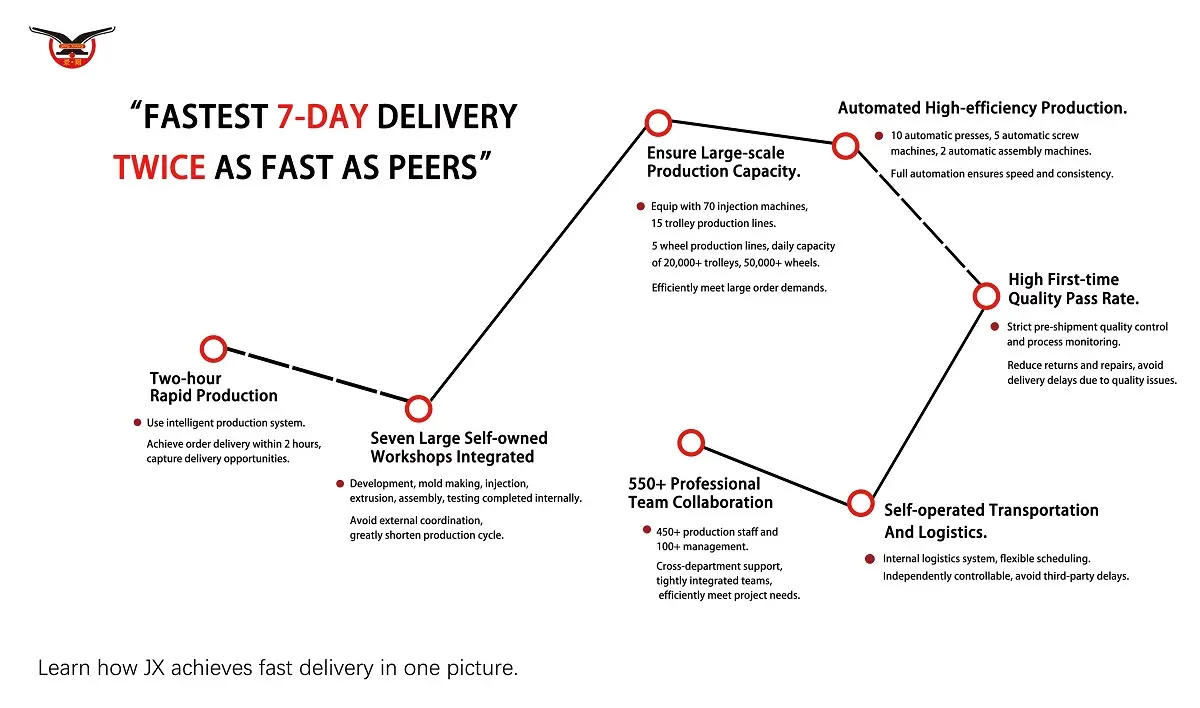

Speed: We offer delivery in as little as 7 days—twice as fast as the industry average.

Quality: We maintain a yield rate exceeding 99%, placing us at the forefront of the industry.

Solving the Industry’s Biggest Challenge

Market data shows that luggage brands often struggle to balance delivery lead times with product quality. JX Luggage Parts resolves this conflict through a highly specialized, vertically integrated manufacturing ecosystem designed to guarantee both speed and consistency for our brand partners.

How JX Luggage Parts Guarantees Rapid Delivery

- 2-Hour Response Time: Utilizing our smart EMS production system, we initiate production scheduling within 2 hours of order placement.

- Vertically Integrated Manufacturing: We operate 7 specialized workshops (R&D, Mold, Injection, Extrusion, Stamping, Anodizing, Assembly, and Testing). By keeping the entire lifecycle in-house, we eliminate outsourcing delays.

- High-Volume Capacity: Equipped with 70 injection molding machines, 15 trolley lines, and 5 wheel assembly lines, we produce over 20,000 trolley sets and 50,000 wheels daily.

- Automated Efficiency: Our facility features fully automated injection workshops and advanced machinery (automatic punching, screwing, and assembly), ensuring high-speed, standardized production.

- “Right First Time” Protocol: Strict pre-production and in-process quality controls minimize rework, preventing delivery delays caused by quality issues.

- In-House Logistics: Our self-operated logistics fleet ensures flexible scheduling and autonomous control, avoiding third-party transport delays.

- Expert Team Collaboration: A dedicated workforce of 450+ production staff and 100+ management personnel ensures seamless project execution.

Get A 7-day Express Delivery Quote!

How JX Luggage Parts Guarantees Stable Quality

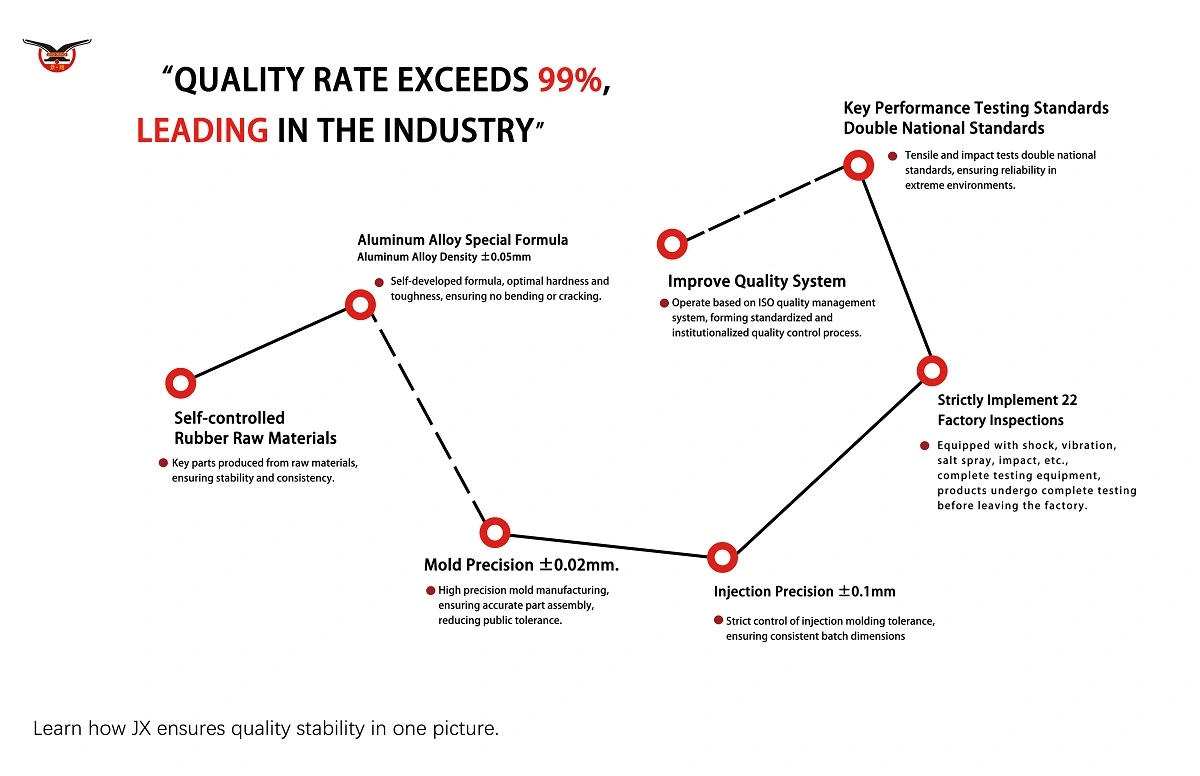

- Premium Raw Materials: We control quality at the source by using 100% virgin materials for critical plastic components.

- Exclusive Aluminum Formula: Our proprietary alloy formula offers the perfect balance of hardness and toughness to prevent bending or snapping. (Precision: ±0.05mm).

- High-Precision Molds: Our molds are manufactured to a precision of ±0.02mm, ensuring tight component fit and minimal tolerance errors.

- Injection Molding Accuracy: We strictly control injection molding tolerances to ±0.1mm for consistent part dimensions.

- Rigorous Testing (22 Protocols): Every product undergoes comprehensive testing, including oscillation, mileage, drop, fatigue, wobble, salt spray, and impact tests.

- Exceeding Standards: Our fatigue and oscillation testing standards are 2x higher than the National Standard, ensuring reliability in extreme conditions.

- ISO Certified System: Our quality control is institutionalized through a robust ISO quality management system.

By choosing JX Luggage Parts, you gain not only a scalable and precise end-to-end solution but also industry-leading quality assurance (over 99% yield rate) and rapid market response capabilities (delivery in as little as seven days). With innovation and superior quality, we are committed to becoming your best partner for durable parts and efficient delivery.

Please don’t hesitate to contact us if you have any questions or concerns.

CONTACT US!

.webp)